The wheel hub is directly connected to the axle shaft or is an extension of the same. The inner end of the axle shaft is splined and is supported by the final drive unit, whereas the outer end is supported by a single bearing inside the axle casing. In this case, the axle shaft is supposed to take the vehicle weight, driving torque, braking torque, and end thrust.

The loads listed above are taken by the axle shaft. The vehicle load is transmitted to each of the half shafts through the casing and the bearing. This causes a bending load and a tendency to shear. Besides, the side forces also cause end thrust and bending moment in the axle shafts, which have to take the driving torque also. The semi-floating axle is the simplest and cheapest of all types, and hence is widely used on cars.

FULL-FLOATING AXLE

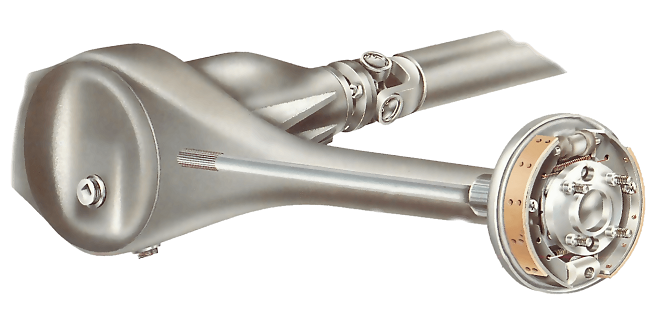

This type is a very robust one and is used in heavy vehicles. The axle shafts have flanges at the outer ends, which are connected to the flanged sleeve by means of bolts. There are two taper roller bearings supporting the axle casing in the hub, which take up any side load. Thus in this the axle shafts carry only the driving torque.

The weight of the vehicle and the end thrust are not carried by them, the weight is completely supported by the wheels and the axle casing. As the axle shafts carry only the driving torque, their failure or removal does not affect the wheels. Thus the axle shafts can be taken out or replaced without jacking up the vehicle. For the same reason, the vehicle can be towed even with a broken half-shaft. However, it is the costliest type.

THREE QUARTER FLOATING AXLE

This is a compromise between the more robust full floating type and the simplest semi-floating type. In this, the bearing is located between the axle casing and the hub instead of between the axle casing and the shaft as in the case of a semi-floating axle.

As is clear from the figure, the axle shafts do not have to withstand any shearing or bending actions due to the weight of the vehicle, which are taken up by the axle casing through the hub and the bearing, provided the bearing lies in the plane of the road wheel. However, it has to take the end loads and the driving torque.

At one time this type of axle was popular in cars and light commercial vehicles. However, with improvements in design, materials, and fabrication techniques, cheaper and simple semi-floating axles are being preferred these days over the three-quarter floating types.

Last word

Inspect each tooth for any pitting or broken tip on the crown wheel, pinion, sun gear, and planetary pinion. Measure the teeth on the crown and pinion to find out the differential reduction.

Tech Readers

Tech Readers